Kubota tractor engines are a prominent force in the industrial power sector, boasting a nearly century-long legacy of dependable performance. Since 1922, Kubota has maintained a significant degree of control over its manufacturing process, a strategy known as "vertical integration." This approach contributes to consistent quality control and potentially lower production costs, solidifying their reputation for reliability. But what specifically sets Kubota engines apart, and how do they fare against competitors? Let's delve into the details. For more on Kubota's history, check out this link to Kubota history.

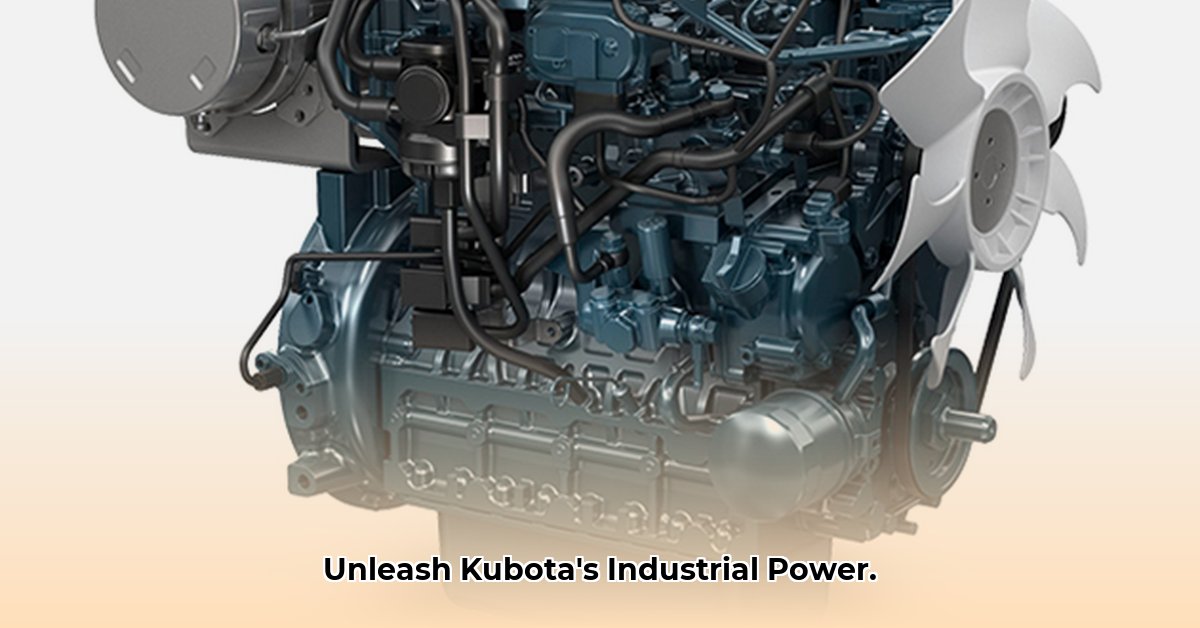

Kubota's Engines: Efficiency in Action

Kubota's fuel efficiency stems from a blend of innovative design and precise engineering. Features such as their advanced crankcase designs—while seemingly minor—contribute substantially to long-term fuel savings. This is especially critical in cost-sensitive sectors like agriculture and construction. Kubota's engine range caters to diverse needs, offering smaller power units for light-duty applications and larger, high-output engines like the award-winning V5009 (recipient of a "Diesel of the Year" award in 2019). This versatility ensures a suitable engine is available for practically any industrial task. How does this efficiency translate to real-world savings? Detailed studies would be needed to offer exact figures.

Keeping Up with the Rules: Emissions and Regulations

Meeting stringent environmental regulations is paramount. Kubota has a strong track record of compliance, readily achieving certifications such as CARB (California Air Resources Board) and consistently adhering to Tier 4/Stage IV emission standards. However, the ever-evolving regulatory landscape demands continuous innovation to maintain compliance and a competitive edge. Kubota's ongoing investment in research and development will be vital in maintaining their leadership in this area. What are the potential penalties for non-compliance? Failure to meet these standards, depending on jurisdictional laws, could lead to significant fines and market restrictions.

How Do Kubota Engines Stack Up Against the Competition?

Kubota holds a significant position within the compact diesel engine market. However, a direct comparison with competitors like Cummins or Caterpillar necessitates access to detailed performance data, including torque curves and fuel consumption under various operating conditions. Such data would provide a robust basis for evaluating Kubota's competitive advantages. Currently, a definitive assessment is challenging without more granular information.

What's Next for Kubota and its Engines? Actionable Steps for Stakeholders

The future of Kubota's engine business hinges on several key factors. Here's a breakdown of actionable steps for various stakeholders:

1. For Kubota Engineers:

- Enhance engine documentation: Providing detailed specifications improves transparency and assists customers and partners, ultimately facilitating more effective decision-making.

- Conduct thorough competitive benchmarking: Direct head-to-head comparisons with competitors using standardized testing methodologies will illuminate Kubota's strengths and weaknesses.

- Invest in alternative fuel engine technologies: Research and development efforts focused on sustainable fuels are crucial for long-term market viability, given ongoing environmental concerns and the transition towards greener energy sources.

2. For Equipment Manufacturers (OEMs):

- Conduct rigorous engine evaluations: A thorough assessment of Kubota engine performance specifics is vital to ensure optimal integration into machinery designs.

- Leverage Kubota's global service network: Access to a widespread network minimizes downtime and streamlines maintenance and repair processes.

- Implement sophisticated engine monitoring systems: Real-time data provides valuable insights into engine performance and detects potential issues proactively.

3. For Investors and Analysts:

- Closely monitor Kubota's financial performance: Tracking key financial indicators such as revenue, profit margins, and R&D spending provides valuable insight into the company's financial health and future prospects.

- Evaluate Kubota's R&D investments: A significant commitment to research and development is crucial for long-term innovation and adaptation to evolving market needs.

- Assess Kubota's long-term market competitiveness: Analyzing market share, competitive dynamics, and future industry trends will unveil potential risks and future growth opportunities.

The Ups and Downs: Risks and Rewards for Kubota

Kubota faces several potential challenges in maintaining its market position. The following table outlines key risks, their likelihood, potential impact, and suggested mitigation strategies:

| Risk Factor | Probability | Impact | Mitigation Strategies |

|---|---|---|---|

| Increased Competition | Medium | High | Product differentiation, strategic partnerships, continuous innovation |

| Changing Emission Rules | High | High | Proactive R&D, early adoption of new emission technologies |

| Supply Chain Problems | Medium | Medium | Supplier diversification, strategic sourcing, robust inventory management |

| Global Political Issues | Low | High | Geographic diversification, proactive risk management |

Kubota's ability to navigate these challenges will be instrumental in determining its long-term success. Proactive adaptation and strategic decision-making are key to maintaining market leadership.

How to Compare Kubota V5009 Engine Specs to Competitors

The Kubota V5009 engine presents a compelling case study in industrial engine design. Effective comparison requires a comprehensive approach focusing on key performance indicators:

Understanding the V5009's Strengths

The V5009 stands out due to its high power density: significant power output from a compact package. This advantage translates to improved machine design, reduced weight, and superior fuel efficiency. Furthermore, its user-friendly maintenance features—such as single-sided access—minimize downtime and maintenance costs.

Comparing the V5009 to Competitors

A robust comparison necessitates a multi-faceted analysis:

- Power-to-Weight Ratio: A higher ratio suggests greater efficiency and performance per unit of weight.

- Fuel Efficiency: Lower fuel consumption (l/kWh or gph/hp) indicates superior efficiency.

- Emissions Compliance: Verify compliance with all relevant environmental regulations.

- Maintenance Costs: Estimate the cost of regular maintenance and potential repairs.

- Total Cost of Ownership (TCO): Consider purchase price, fuel costs, maintenance, and downtime for a holistic cost assessment.

- Durability and Reliability: Examine independent testing reports and user feedback to gauge long-term reliability.

Key Considerations Beyond Specifications

Beyond technical specifications, consider these factors:

- Warranty and Service Network: A strong warranty and service network mitigates operational risks.

- OEM Partnerships: The number and type of OEMs using the V5009 reflect its market acceptance.

- Technological Advancements: Evaluate any unique technological features of the V5009.

Actionable Insights

- For Kubota: Ongoing investment in R&D and rigorous testing are vital.

- For OEMs: Close collaboration with Kubota for performance improvements.

- For End-Users: A comprehensive cost-benefit analysis is essential before purchase.

Key Takeaways:

- The Kubota V5009 excels in power density and ease of maintenance.

- Complete comparisons necessitate a multi-faceted approach.

- Total Cost of Ownership (TCO) is the primary benchmark for long-term value.

- Assessing long-term reliability data is critical for informed decision-making.